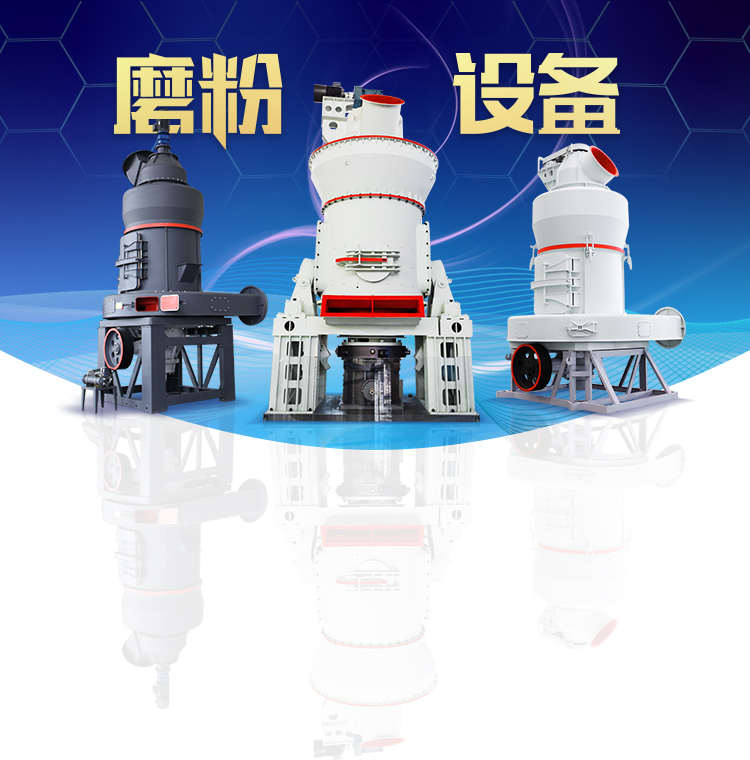

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Ball Mills With Ceramic Lining

Ceramic Ball Mill

2024年7月13日 Ceramic ball mill is a ball mill whose lining plate is made of ceramic It has a small capacity and is generally suitable for small batch production in the product trial Continuous Ceramic Ball Mill HJMT® continuous ball mill now is used by more and more factories with the advantages of the good economic benefits, Continuous Ceramic Ball Mill HJMTWith over 5 decades of manufacturing experience in technical ceramics coupled with modern manufacturing facilities, we at Jyoti Ceramic offer CAD/CAM designed, custom engineered mill CERAMIC BALL MILL LINING BRICKS AND GRINDING MEDIADiscover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining Ideal for ceramic, chemical, metallurgical, and Stainless Steel Laboratory Ball Mill for Dry Ceramic ball mill lining is widely used in power plants, steel mills, chemical, rubber, and coating fields, is the ideal surface wearresisting material for material transfer equipment in mining, iron steel works, thermal powder plants, Ceramic Ball Mill Lining2023年10月25日 The ceramictype batch ball mill is a small noncontinuously produced ball mill The utility model has the advantages of simple structure, convenient operation, less auxiliary equipment, and highdefinition products Sinogomine Industrial Technology Co,Ltd

.jpg)

Ceramic Ball Mill ContaminationFree Grinding

Zoneding Mining manufactures reliable Ceramic Ball Mills with highpurity ceramic lining, ensuring contaminationfree wet/dry grinding for ceramics, chemicals more Get Quote!Import Ball Mill with Cooling Water and Ceramic Lining (64CBM) directly from China factory, Wuxi Huihao stone stone Machinery Co, Ltd, and enjoy FREE trade Vulco mill lining systems Ball Mill Ceramic Lining Crusher Mills2024年7月13日 Advantage Of Ceramic ball mill Ceramic ball mill reduces replacement frequency of easily damaged parts at the most extent Lining plates ,steel balls are made of Ceramic Ball MillBall mill liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates The MultoMet range utilises Hardox 500 wearresistant steel attached to the leading edges of the lifter bar Ball Mill Linings MultotecCeramic ball mill lining is widely used in power plants, steel mills, chemical, rubber, and coating fields, is the ideal surface wearresisting material for material transfer equipment in mining, iron steel works, thermal powder plants, Ceramic Ball Mill Lining2020年5月19日 The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media and the material Ball Mill Liners Selection and Design Ball Mill Rubber Liner

Mill Linings for Sale, Types of Ball Mill Liners ball mills

The ball mill liner has the advantages of low energy consumption, high wear resistance, low noise, and easy installation Through the actual test, compared with manganese steel lining, the ball 2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ Ball Mills 911MetallurgistThe ball mill ceramic wearresistant lining plate consists of three parts: the ball mill straight plate, the ceramic guard plate and the bolts This design is simple in structure, convenient in The Role Of Wearresistant Ceramic Liner in Ball MillThese materials include AR 400, highchrome abrasion resistant steel, natural rubber lining, polyurethane lining, and high alumina ceramic brick (ie, aluminum oxide) lined mills Slice Ball Mill Application and Design Paul O AbbePaul O Abbe Equipment Company is a manufacturer New Ceramic Lined Ball Mills and Milling Equipment Call 8005242188 or request a quote to get started About Section 179; 630350 Ceramic Lined Ball Mills Paul O Abbe4 天之前 Ceramic lined ball mill is used to grind down raw materials into very fine particles It is specifically designed for high purity material powder productionRaw materials such as Ceramic ball millBaichy Machinery

Tega DynaWear Rubber Mill Liner Manufacturer

The Tega DynaWear® rubber lining system is the preferred lining system for secondary ball mills, regrind mills and scrubbers DynaWear® rubber mill linings are individually designed for your particular working conditions and goals, with Ball mills are available with a grinding drum made of porcelain (100250 litres) or steel, with a lining of steatite or aluminium oxide (4012,000 litres) The ball mills are also equipped with a Ball mills KERAWe offer ball and pebble mill grinders with the option for ceramic interior lining to enable greater efficiency The ceramic lining comprises aluminum oxide brick, a hard material that increases HighQuality Ball Mills for Efficient Grinding PulvaCeramic ball mill linings will eventually wear down and need replacement Even old pebble mills with Burrstone linings can be relined with highalumina brick We tear out and dispose of the Ceramic Ball Mill Relining and Refurbishing Paul O Abbe2024年8月8日 Ceramic balls offer high durability and minimal contamination, making them ideal for applications requiring high purity Steel balls, recognized for their robustness, are better Ball Mill Success: A StepbyStep Guide to Choosing precise ceramicCeramic ball mill is also called ceramic ball mill machine It is a kind of industrial ball mill that the liner plate is made of wearresistant ceramics The lining plate is detachable Users can Ceramic Ball Mill For Sale – Automatic Ceramic Ball Mill

.jpg)

High Alumina ceramic lining Bricks

Alumina lining brick can protect ball mill from wear Alumina Ceramic Lining Brick is widely used in ceramics, cement and other industry Skip to content +86 24/7 Customer 2025年4月2日 Wearresistant ceramic lining can still maintain good performance at high temperature, is not easy to deform, and is not affected by thermal expansion and contraction Application of WearResistant Ceramic Liner in Ball MillMosaic ceramic lining pieces; Ball mill lining brick; Ceramic tubes and specialshaped parts; Silicon carbide wear ceramics; glasses, and enamels in chemical factories and other CERAMIC GRINDING BALLFIRSTA,CERAMIC WEAR LINING,CERAMIC GRINDING BALL Industrial Ceramic Linings advantages: Multotec’s wear resistant industrial ceramic lining tiles can be cut into any shape, are easy to install and maintain, and are suitable for both wet and dry Industrial Ceramic Linings MultotecThe highenergy vibrating ball mill is a highenergy oscillating and impacting multifunctional laboratory ball mill The tabletop type is easy to operate, small in size, comfortable and safe Discover the versatile stainless steel dry High Energy Vibratory Ball Mill For Lab UseWe have a wide range of inhouse built and imported ball mills Both batch and continuous feed mills are available with steel, rubber or ceramic replaceable lining Both batch and Ball Mills Armstrong Industries

Ceramic Ball mill lining 95% Zirconia BrickBall

95% zirconia lining bricks are a type of ceramic brick used in industrial applications such as ball mills, attritors, and vibroenergy grinding mills These bricks are made of a highpurity zirconium oxide (ZrO2) material with a We are manufacturing ball mill, rubber mill liner, ball mill rubber liner for ceramic, minerals, mines, mill lining industries We are dealing in Rubber liners above thickness 30 mm Consider The Flexible Rubber Liner Manufacturer,Mill Liner Plate Ball Mill Lining worth $3,238,133 under Sub Chapter 8474 have been imported; Average import price for ball mill lining under Sub Chapter 8474 was $24121 Please use filters at the bottom Ball Mill Lining Imports Under Sub Chapter 8474 ZaubaBall mill liners from Multotec maximise the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners availableRefined through ongoing design Ball Mill Liners MultotecCeramic Ball, WearResistant Materials, Ceramic Grinding Media, Ceramic Lining, Ceramic Lined Pipe, Ceramic Rubber Liner More Company Introduction The company covers an area of Ceramic Ball Manufacturer, WearResistant Materials, Ceramic A variety of liners can be selected for mini ball mills: alloy steel lining, stainless steel lining, wearresistant polyurethane lining, ceramic lining, zirconia lining, etc The ball mill reducer and gear Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale

Application of alumina wearresistant lining brick in ball mill

Alumina wearresistant ceramic lining bricks can increase the service life of ball mill linings We analyze from the following perspectives: Working principle of ball mill: As an important Available cylinder sizes range from laboratory mills to 12′ in diameter Discharge Features For discharge of the product on wet grinding processes we offer our standard media retention Orbis Machinery Ball Mills Ball Mill Drive2024年7月13日 Advantage Of Ceramic ball mill Ceramic ball mill reduces replacement frequency of easily damaged parts at the most extent Lining plates ,steel balls are made of Ceramic Ball MillBall mill liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates The MultoMet range utilises Hardox 500 wearresistant steel attached to the leading edges of the lifter bar Ball Mill Linings MultotecCeramic ball mill lining is widely used in power plants, steel mills, chemical, rubber, and coating fields, is the ideal surface wearresisting material for material transfer equipment in mining, iron steel works, thermal powder plants, Ceramic Ball Mill Lining2020年5月19日 The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media and the material Ball Mill Liners Selection and Design Ball Mill Rubber Liner

Mill Linings for Sale, Types of Ball Mill Liners ball mills

The ball mill liner has the advantages of low energy consumption, high wear resistance, low noise, and easy installation Through the actual test, compared with manganese steel lining, the ball 2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ Ball Mills 911MetallurgistThe ball mill ceramic wearresistant lining plate consists of three parts: the ball mill straight plate, the ceramic guard plate and the bolts This design is simple in structure, convenient in The Role Of Wearresistant Ceramic Liner in Ball MillThese materials include AR 400, highchrome abrasion resistant steel, natural rubber lining, polyurethane lining, and high alumina ceramic brick (ie, aluminum oxide) lined mills Slice Ball Mill Application and Design Paul O AbbePaul O Abbe Equipment Company is a manufacturer New Ceramic Lined Ball Mills and Milling Equipment Call 8005242188 or request a quote to get started About Section 179; 630350 Ceramic Lined Ball Mills Paul O Abbe4 天之前 Ceramic lined ball mill is used to grind down raw materials into very fine particles It is specifically designed for high purity material powder productionRaw materials such as Ceramic ball millBaichy Machinery

高岭土磨粉机工作视频

--石灰石碳酸钙磨粉机热解炭黑室用

--50吨球磨机

--中速磨煤机共有几种

--水泥厂用熟料

--矿山雷蒙机

--0 10 9012雷蒙磨一小时能打多少

--徐州冠力滑石粉设备雷蒙磨有限公司徐州冠力滑石粉设备雷蒙磨有限公司徐州冠力滑石粉设备雷蒙磨有限公司

--环辊磨 加什么油环辊磨 加什么油环辊磨 加什么油

--Weighing Belt Conveyor For Chrome In Mexico

--筹建方解石矿需要办哪些设备

--铅粉 超微粉

--碳酸钙矿石制粉

--开设临时粉体机械厂的请示

--中速立磨减速机

--采矿粉要什么证件

--mtm梯形磨粉机销售点

--石灰石加工设备厂家

--上海重晶石磨粉机厂

--碎精品砂粉设备价格及图片

--山东省矿石磨粉机招标网

--广东佛山钠长石矿石深加工情况

--矿石磨粉机问题解答

--重钙粉埃及碳酸盐碳酸钙磨粉机雷蒙磨

--高岭土磨粉机生产厂家

--建筑石膏抗压强度检测示意图

--东北粉煤灰加工纯石灰石粉碎机雷蒙机粉机

--粉碎站操作规程

--生产煤磨设备

--徐州滑石粉设备雷蒙磨时代大道

--