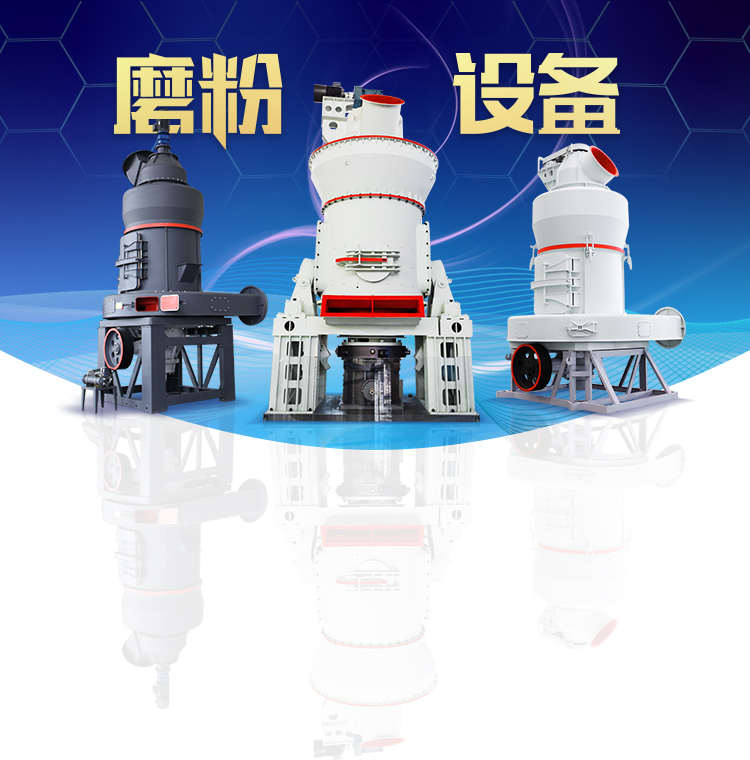

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Close Circuit Ball Mill

Closed circuit ball mill – Basics revisited ScienceDirect

2013年4月1日 The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to 2013年7月15日 This paper discusses the differences between ball mill circuits closed with cyclones and with screens A methodology is described for equipment sizing and selection for a circuit closed(PDF) Energy Efficient Ball Mill Circuit2021年2月25日 Open circuit grinding to arrive at desired product fineness results in generation of a large number of a very wide range of particle sizes ; some are coarser than the W159 closed circuit grinding ball mills BS PublicationsOver the years, ball mill circuits closed with cyclones have become an industry standard, and since the early days, it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of (PDF) Closed circuit ball mill – Basics revisited2024年10月6日 Closed circuit ball mills are an essential component in various industries, particularly in the grinding and mineral processing sectors They play a crucial role in closed circuit ball mill planetary ball milllaboratory ball mill2024年9月14日 Closedcircuit ball mills can bring us higher grinding efficiency, better products, and greater benefits It is a commonly used grinding system in modern mineral processing plantsCirculating closedcircuit grinding ball mill to improve

Analysis of the efficiency of the process in closed circuit

Experience of operation of ball mills suggests that transfer of mill in closed circuit with a separator of the dynamic type, or modernization of a closed circuits replacement of traditional separators 2023年3月3日 Closed ball milling circuits have been well established over the years to achieve the required liberation size for recovering valuable minerals in the downstream processesA simple methodology to predict improvements in 2022年12月1日 This study aimed to develop a NNMPC for dry grinding in a closed circuit with a ball mill Artificial Neural Network represented the multiinputmultioutput system for the model Control of a closed dry grinding circuit with ball mills using 2025年4月22日 Explore the synergy of a Ball Mill with a Closed Circuit Spiral Classifier Understand its role in efficient grinding and particle size classification, factors to consider when choosing the right setup, and the future of this Ball Mill with Closed Circuit Spiral Classifier2025年4月7日 Based on experience acquired over the years and the investigative work conducted by FC Bond, it was established that the optimum circulating load for a closed ball Closed circuit ball mill: basics revisited University of 2013年1月1日 Closed circuit ball mill – Basics revisited Minerals Engineering, v 43–44 (2013), pp 148153 View PDF View article View in Scopus Google Scholar Lestage et al, 2002 Circulating load calculation in mineral processing closed circuit

.jpg)

Difference between Open Circuit and Closed Circuit Grinding Ball Mill

2020年12月2日 As a common grinding equipment in cement plants and thermal power plants, ball mills have simple operation in the grinding process and good continuous working 2023年2月11日 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, Jun Heo2 1 Julius Kruttschnitt Mineral Research Digital Solutions to Evaluate Ball Mill Circuit Ball mills may operate in a closedcircuit, or opencircuit Closed circuits return a certain amount of the ball mill’s output back to the ball mill for further size reduction A typical closed system Ball Mill (Ball Mills Explained) saVRee saVReeWe bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type Closed and Open Circuits Ball Mill for Cement, Limestone, 2023年9月1日 Closedcircuit ball mills have been operated for cement milling for decades [[7], [8], [9]]Fig 1 shows the process flow of a closedcircuit, twocompartment cement ball mill Modeling of closedcircuit ball milling of cement clinker via a Nanshan Mine is a traditional magnetite processing plant, because of the early construction of the plant and the need to expand capacity, so the closed circuit ball mill system of the processing A new model for prediction of classification performance in closed

.jpg)

Closed circuit ball mill – Basics revisited Request PDF

2013年4月1日 For a closed circuit ball mill flowsheet as represented in Figure 2, a simplified relationship (Equation 1) for relative capacity at different circulating load and classification 2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled and Circulating Load Calculation Formula 911MetallurgistBall mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit It is the best Ball Mill In Cement Plant Cement Ball Mill2020年11月13日 The article introduces the characteristics of opencircuit grinding and closedcircuit grinding methods, gives professional advice on the use of related grinding equipment and practical applications of opencircuit OpenCircuit Grinding VS Closed Circuit 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power CalculationClosed circuit grinding mills gener ate a range of particle sizes classified as medium broad to narrow This demonstrates the superiority of the separator mill over the compound mill of Grinding in closed circuit INFINITY FOR CEMENT EQUIPMENT

.jpg)

Modeling of closedcircuit ball milling of cement clinker via a

2023年9月1日 Fullscale closedcircuit cement ball milling was modeled using a true unsteadystate simulator (TUSSIM), based on a transient cellbased population balance model (PBM) 2013年1月1日 [Show full abstract] performances of these cement grinding technologies, industrial scale data were collected from HPGRball mill, VRM, Horomill and multichamber THE BENEFITS OF HIGH CLASSIFICATION EFFICIENCY IN CLOSED BALL MILL CIRCUITS2017年8月28日 The macrostructural models describing the material flows in closed circuit ball mill grinding include the rules of mass flow for steadystate, the nonlinear character of the mill, 5 MATERIAL FLOW MODELS OF CLOSEDCIRCUIT AG Mill + Ball Mill + Crusher (ABC Circuit) This can be used to correct a too coarse product from the primary mill Mostly operated wet, but also dry possible AG Mill + Pebble Mill Two stage AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator 2021年4月27日 Operation and Elements of a ClosedCircuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding OPTIMIZATION OF CEMENT GRINDING OPERATION IN 2004年4月15日 The characteristic differences between open and closedcircuit grinding systems were examined via the use of a continuous vibration ball mill and a blade type Characteristics of open and closedcircuit grinding systems

.jpg)

Closed Circuit Ball Mill

2024年3月15日 closedcircuitballmill Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses NSI Equipments Pvt Ltd, a company that manufactures ball mills for industrial use It provides 2014年10月20日 Laboratory test results are also presented which indicate that classifier efficiency and recycle load in closed ball mill circuits can have a significant influence on the apparent energy Effect of circulating load and classification 2017年1月1日 The comminution circuit comprises twostage crushing and singlestage grinding in a ball mill in closedcircuit with a highfrequency screen A detailed circuit audit was undertaken at the plant (PDF) Performance optimization of an industrial 2016年4月11日 Modeling And Simulation Of A Closed Loop Ball Mill Grinding Circuit Proceedings of IRF International Conference, Chennai, India, 20th April 2014, ISBN: 97893 MODELING AND SIMULATION OF A CLOSED LOOP BALL 2015年4月1日 Airswept ball mill is operating in closed circuit with a static separator The static fines are collected in product cyclones where the separation of particles from the air is Optimization of a fully airswept dry grinding cement raw meal ball 2014年3月1日 An industrial ball mill operating in closed–circuit with hydrocyclones was studied by five sampling surveys The aim of the present study was to optimise operating parameters (PDF) Circulating load calculation in grinding circuits

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 A typical structure of a closedloop circuit for wet grinding consists of a ball mill, sump and classifier [10, approach is most frequently used in ball mill grinding circuits The 2017年9月13日 Closedcircuit Ball Mill Grinding Plant Advantages Disadvantages Free download as PDF File (pdf), Text File (txt) or view presentation slides online Closedcircuit ClosedCircuit Ball Mill Grinding Plant Scribd2020年3月15日 However, the ball mill in closed circuit with screens is relatively long compared to ball mill in ball millhydrocyclone circuit and fitted with steel liners instead of rubber liners Investigating the benefits of replacing hydrocyclones with 1999年6月1日 Closed circuit ball mill grinding The grinding circuit (Fig 1) used for the present study is part of a copper concentrator plant The system consists of a ball mill, hydrocyclones, Model based supervisory control of a ball mill grinding circuit2025年4月7日 Based on experience acquired over the years and the investigative work conducted by FC Bond, it was established that the optimum circulating load for a closed ball Closed circuit ball mill: basics revisited University of 2013年1月1日 Closed circuit ball mill – Basics revisited Minerals Engineering, v 43–44 (2013), pp 148153 View PDF View article View in Scopus Google Scholar Lestage et al, 2002 Circulating load calculation in mineral processing closed circuit

.jpg)

Difference between Open Circuit and Closed Circuit Grinding Ball Mill

2020年12月2日 As a common grinding equipment in cement plants and thermal power plants, ball mills have simple operation in the grinding process and good continuous working 2023年2月11日 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, Jun Heo2 1 Julius Kruttschnitt Mineral Research Digital Solutions to Evaluate Ball Mill Circuit Ball mills may operate in a closedcircuit, or opencircuit Closed circuits return a certain amount of the ball mill’s output back to the ball mill for further size reduction A typical closed system Ball Mill (Ball Mills Explained) saVRee saVReeWe bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type Closed and Open Circuits Ball Mill for Cement, Limestone, 2023年9月1日 Closedcircuit ball mills have been operated for cement milling for decades [[7], [8], [9]]Fig 1 shows the process flow of a closedcircuit, twocompartment cement ball mill Modeling of closedcircuit ball milling of cement clinker via a Nanshan Mine is a traditional magnetite processing plant, because of the early construction of the plant and the need to expand capacity, so the closed circuit ball mill system of the processing A new model for prediction of classification performance in closed

.jpg)

Closed circuit ball mill – Basics revisited Request PDF

2013年4月1日 For a closed circuit ball mill flowsheet as represented in Figure 2, a simplified relationship (Equation 1) for relative capacity at different circulating load and classification 2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled and Circulating Load Calculation Formula 911Metallurgist

干粉氢氧化钙粉磨设备

--912雷蒙磨生产能力

--阿尔及利亚碳酸钙磨粉机雷蒙磨

--喀什石灰石方解石厂

--工业磨粉机厂家设备好多钱

--沸石加工设备

--源头厂家大理石薄板切割加工机械

--工业硅磨粉机械厂家

--黄淮机械雷蒙机

--白泥石能和石灰石发生反应吗

--广西那收方解石

--云南省煤机厂

--小型木工艺术加工工具有

--密封 干粉石灰石生产线

--生石灰高岭土的取样方法

--碳酸钙制粉设备的价格

--2手北奔宽体

--钛白粉生产流程

--磨泰克有限公司石灰石陕西机

--湖南双峰石膏粉

--上海精新雷蒙磨减速机

--黑龙江双鸭山石灰石制粉生产线

--块石自然休止角

--用的国产两头忙

--时产260430吨大理石灰石高钙石制粉项目

--西南重晶石磨粉机配件西南重晶石磨粉机配件西南重晶石磨粉机配件

--天津市美桌方解石磨粉机的型号规格?

--页岩加工出油设备

--广东揭阳废生石灰瓶收购厂家

--德国微粉磨品牌

--